Technology

THE CadTel EDGE

CadTel ADVANTAGE OVER SI MODULES

CadTel

- Stronger BIPV performance

- CadTel produces more energy per rated power

- Favorable bandgap for atypical directional orientation.

- Lowest carbon footprint

- Longer lifespan making CadTel the ideal material for long-term placement into a building envelope

- Lighter weight module that is compatible with existing practices for spandrel and vision glass installation

Silicon PV

- Silicon PV cells are fragile, crack very easily and are subject to heat overload failure- even on cool days.

- More than 90% of Silicon PV Solar cells are made in China.

- Silicon PV semi-conductors are sensitive to mild heat, and are NOT well aligned with the Sun’s light spectrum.

The Silicon Problem

The average Silicon production cycle requires roughly 5 manufacturing plants and immense labor and energy. Silicon Modules are sensitive to heat, hail, and cell cracking.

CadTel SOLUTION

Responsible Recycling

Thin-film CadTel solar glass is 100% recycled in a special-purpose facility, with over 90% of all materials being used, whereas silicon panels are mostly scrapped in local landfills, creating a major hazardous waste problem.

Environmentally Friendly

Silicon PV solar cells require 2.5 times more energy to produce and are not recycled. CdTe is 100% recycled on an end of life recycling program, and all solar glass is made from 99% recycled materials by weight.

Lifetime Durability

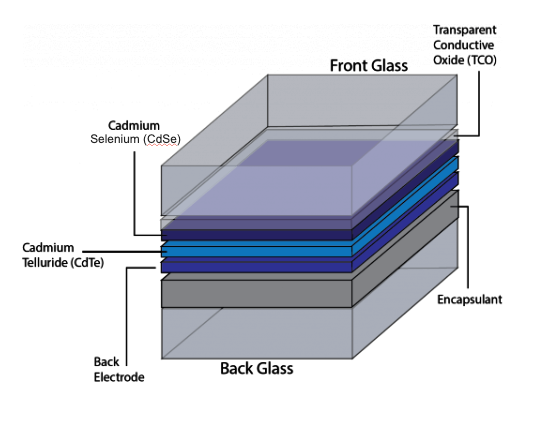

Toledo Solar's sleek black solar glass is manufactured using two sheets of high-strength tempered glass hermetically laminated in a frameless construction making CadTel the ideal material for long term placement on a building envelope.

By contrast, silicon panels typically comprise many parts soldered together that are easily damaged by wind, hail, transport, installation and frequent cleaning in the field.

Production Efficiency

The manufacturing process of CadTel modules gives them inherent advantages over c-Si for BIPV usage – CadTel is applied directly to architectural glass – resulting in a lighter weight module that is compatible with existing practices for spandrel and vision glass installation.